Scientists have found a way to fabricate replacement parts within hours using only water bottles and other recyclable materials

01/27/2019 / By Lance D Johnson

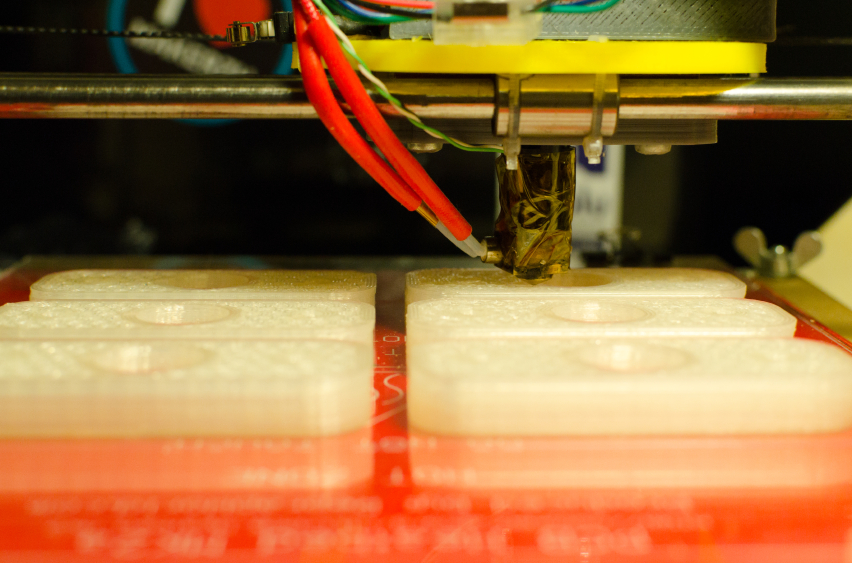

Scientists have found a way to integrate recyclable plastics with cardboard fibers to create a durable filament for 3D printing. These innovations in 3D printing will allow soldiers to recycle empty water bottles, plastic containers, and cardboard packaging so they can make their own replacement parts on base for use on the battlefield. Soldiers will no longer have to wait weeks for vital replacement parts. They will be able to create the parts they need with the materials they throw away on a daily basis.

Lead researcher Nicole Zander, Ph.D. says that soldiers wouldn’t have to depend on outside supply chains for new parts and components. “Instead, they could basically go into the cafeteria, gather discarded water bottles, milk jugs, cardboard boxes and other recyclable items, then use those materials as feedstocks for 3D printers to make tools, parts and other gadgets.”

This will improve operational readiness, enhance safety, and make good use of plastics, which end up contaminating landfills and the beautiful oceans of the world. Zander’s research was presented at the 256th National Meeting & Exposition of the American Chemical Society (ACS). (Related: Learning from nature: Scientists create new material inspired by leaves to separate oil from water for cleaning up oil spills.)

Recyclable plastics and cardboard successfully converted to 3D printing filament for military use

The research team, including U.S. Marine Corps Captain Anthony Molnar and the U.S. Army Research Laboratory, recognized that PET plastics are just as durable as commercial 3D printing filaments. PET plastics include water and soda bottles. Their first successful experiment involved a two hour process and 10 water bottles. They were able to print a durable vehicle radio bracket.

They did not stop there. The researchers wanted to find a way to recycle weaker plastics such as polypropylene, used to make cottage cheese containers, and polystyrene, used to make plastic utensils. In order to do this, they would have to incorporate wood and cardboard fibers to make the filament stronger. Using a process called solid-state shear pulverization; the researchers combined wood flour, paper, and cardboard to generate composite PP/cellulose filaments. The fibers were pulverized into a fine powder using a twin-screw extruder. The fiber is melted down and mixed into the plastic 3D printing filaments, improving the strength and durability of the 3D printing material. This is every recycler’s dream come true.

This is also a dream come true for military efficiency. The U.S. Department of Defense currently manages eight supply chains, with a combined inventory of approximately five million items. These items cannot be stockpiled at front-line locations. If the troops need a new part, it can take days, weeks, or even months for the necessary items to arrive. With this new 3D printing technology, the troops can gather their waste, create the filament they need, and then program the parts they need. All this can happen within a couple hours, speeding up military operations.

To further assist the military’s operations, the scientists are building a mobile recycling trailer to collect usable waste on military bases. This will speed up the process of recycling and help soldiers fabricate their own filaments for on-site 3D printing. The researchers also plan to train the soldiers on how to make the filaments so they can quickly produce their own parts under combat conditions.

For more on new innovations, visit Science.news.

Sources include:

Tagged Under: 3D printing, breakthrough, cardboard, Chemistry, combat readiness, efficiency, environment, innovation, innovations, inventions, military operations, military supplies, military tech, PET plastics, plastic filaments, recycling, supply chains